For More Information... Call Us Toll-Free at: 877-988-5464.

Water-Cooled Process Chillers: As the name indicates, a water-cooled process chiller will reject process heat to another fluid

based medium. In most cases, heat rejection by water-cooled process chiller will go to an outdoor located evaporative cooling tower.

based medium. In most cases, heat rejection by water-cooled process chiller will go to an outdoor located evaporative cooling tower.

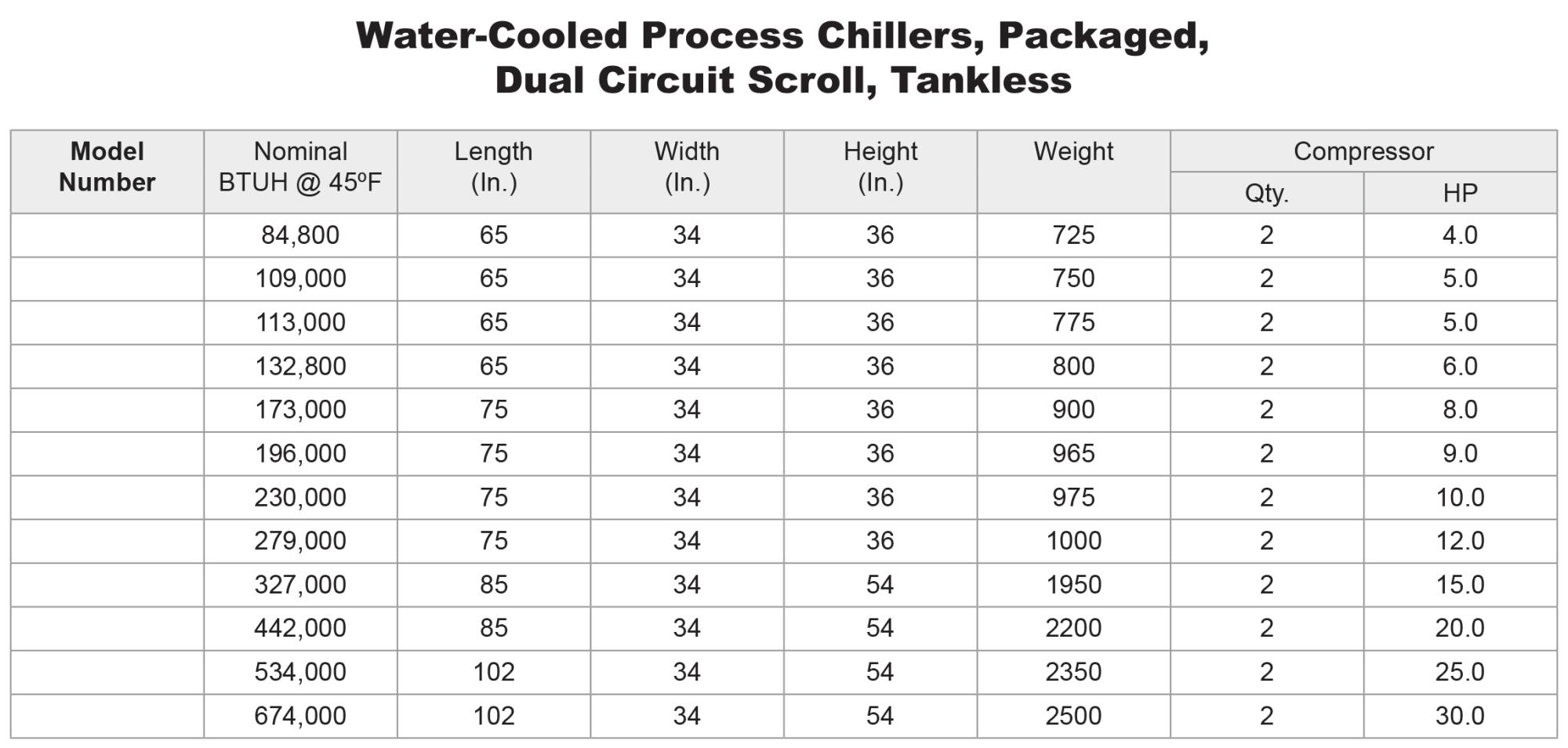

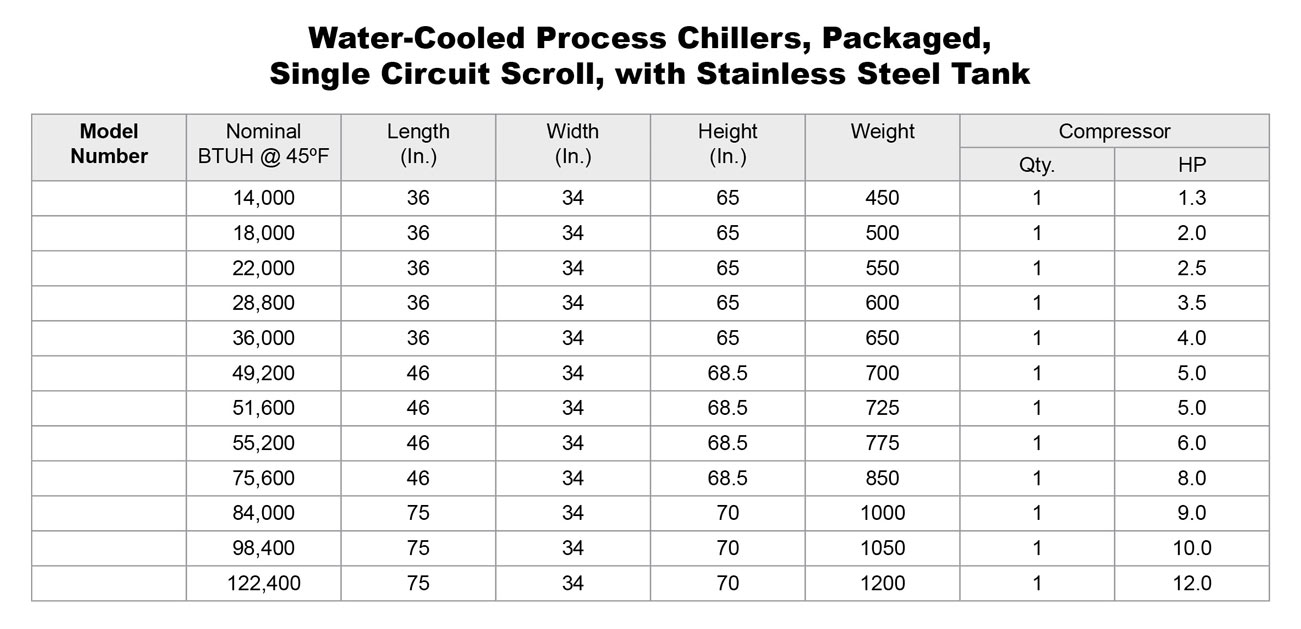

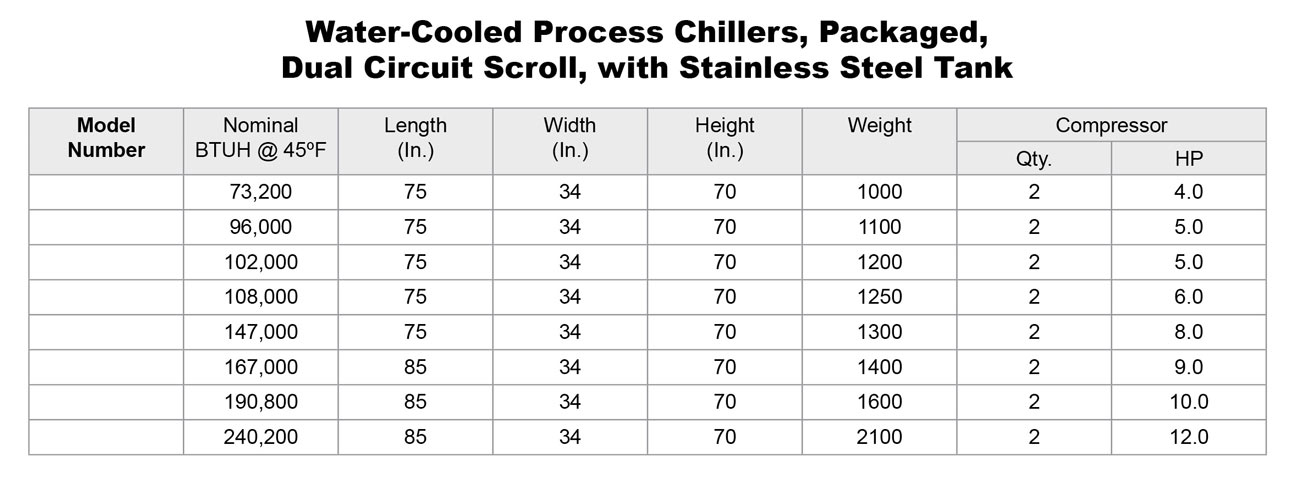

Legacy's model PZW water-cooled chiller system is available from 1 to 120 HP. These systems are very compact and light. Keep in

mind that ALL water-cooled condenser process chillers require a way to reject their heat normally to another water sourse such as

a cooling tower.

Available from 1 to 20 tons, the PZWT's unique dual loop (re-circulatory) flow technology, these chillers are ideal for mission critical applications that require very stable approach temperatures within a 24/7/365 service environment. The PZWT product line is also available with Legacy's Patented Economizer Technology capable of reducing energy usage (depending on operating environment) up to 60%. The PZWT system has been designed from the ground up to be the industry's premier process chiller in its capacity class.

WATER-COOLED

SCROLL PROCESS CHILLERS

Click on a Chiller Model Below to Download a Spec Sheet

Note: Water-Cooled Process Chiller Capacities based on

ARI Standard 45ºF LWT and 105ºF Condensing Temp.

ARI Standard 45ºF LWT and 105ºF Condensing Temp.

Standard Features:

• ETL listed to UL1995 & CAN/CSA C22.2

No. 236-11, 4th edition, 10/14/2011

• Single Point Power Connection

• Idec microprocessor controller with easy to

use touch screen display

• STAINLESS STEEL, brazed plate evaporator

• Scroll compressor with crankcase heater

• Suction Accumulator

• Water flow switch

• Hot Gas Bypass Capacity Control

• 24V control transformer

• Control circuit fusing

• Condenser(s): Coaxial up to PZW22D

• Condenser(s): Shell and Tube PZW26D through PZW52D

• Compressor motor contactor

• Painted - Powder Coated (Most Models),

galvanized sheet metal cabinet

• 1/2” insulation on all water and refrigerant lines

• Liquid line drier, sight glass, solenoid, TXV

• Complete refrigerant charge from factory

• Extended warranty: See your quote or latest IOM booket

revision

• Extended warranty: See your quote or latest IOM booket

revision

Tank Models Only:

• STAINLESS STEEL storage tank with 1/2 inch insulation

• Fused, STAINLESS STEEL re-circulation pump for tank

operation with ball valve and cleanable strainer

• Tank pressure relief valve, vent and drain hose bibs

• Fused, STAINLESS STEEL re-circulation pump for tank

operation with ball valve and cleanable strainer

• Tank pressure relief valve, vent and drain hose bibs

Options:

• Remote Idec touchscreen control panel

• Remote Idec touchscreen control panel

• Industrial VPN Router

• 5 Port Ethernet Switch

• BacNet Gateway

• Process Pump VFD Controller

• 4 year extended compressor warranty

• Casters (factory mounted)

• Condenser water regulating valve

• 115 volt (rain tight) service outlet

• Non Fused Disconnect

• Phase Monitor, line voltage monitor offering protection

against phase loss/reversal, unbalance and hi/lo voltage

against phase loss/reversal, unbalance and hi/lo voltage

• Compressor fusing

• Compressor Sound Cover

• Factory installed evaporator heat tape freeze protection

• Low flow by-pass valve

• Fused, STAINLESS STEEL process pump

• Dual system pump with manual changeover (some models)

• Dual system pump with auto changeover (some models)

• Pump suction isolation valve

• Water pressure gauge set

• Water Flow Meter

• Auto city water changeover panel with filter

• Stainless steel, SCH80 PVC or Polypropylene piping for

deionized and reverse osmosis water systems

• Storage tank sight glass (Tank models only)

• Tank low liquid level indicator with dry contacts

(Tank models only)

• Storage tank sight glass (Tank models only)

• Tank low liquid level indicator with dry contacts

(Tank models only)