LEGACY CHILLER CONTROLS

For More Information... Call Us Toll-Free at: 877-988-5464.

VLT® HVAC DRIVE

• Energy efficient control pumps

and compressors

and compressors

• Precise control of pressure

and flow

• Ensures maximum economy

and low running cost

• Standard interface with

Legacy software - this option

can be added at anytime with

hardware install

Standard Features

• Ultra bright 5.7 inch Color LCD OI Touch Screen with

auto screen saver

• 15 Control Screens with built-in help features.

• Real-time Pressure and Temperature readings

• Real-Time SuperHeat, Subcooling, Chiller Supply and Chiller

Return temperature graphical trending

• Automatic COMPRESSOR Lag/Lead with FIVE operational modes

• Automatic SYSTEM PUMP Lag/Lead with FIVE operational modes.

• Control up to two system pumps

• Manual and auto system pump control from HMI home screen

• Factory configured for ALL Legacy available chiller options.

• Control operates to a +/- 1°F accuracy

• Powered from the chiller 24 volt control circuit.

No high voltage interference.

• Operates and displays in °F

• Controls cooling on inlet or outlet temperature

• Monitors and logs compressor/pump run hours

• USB update slot for IN-PLACE HMI and PLC software updates

available from legacychillers.com website.

• CE, UL Listed

• Built in Web Server via HMI

• SD slot for optional data storage on HMI

• Highly accurate and fast performance

• Embedded Ethernet Port

• Preprogramed remote start/stop set up for customers

dry contact connection.

• Pentra PLC outputs control IDEC's RV1H pilot relays

rated to 6 amps.

• 15 Control Screens with built-in help features.

• Real-time Pressure and Temperature readings

• Real-Time SuperHeat, Subcooling, Chiller Supply and Chiller

Return temperature graphical trending

• Automatic COMPRESSOR Lag/Lead with FIVE operational modes

• Automatic SYSTEM PUMP Lag/Lead with FIVE operational modes.

• Control up to two system pumps

• Manual and auto system pump control from HMI home screen

• Factory configured for ALL Legacy available chiller options.

• Control operates to a +/- 1°F accuracy

• Powered from the chiller 24 volt control circuit.

No high voltage interference.

• Operates and displays in °F

• Controls cooling on inlet or outlet temperature

• Monitors and logs compressor/pump run hours

• USB update slot for IN-PLACE HMI and PLC software updates

available from legacychillers.com website.

• CE, UL Listed

• Built in Web Server via HMI

• SD slot for optional data storage on HMI

• Highly accurate and fast performance

• Embedded Ethernet Port

• Preprogramed remote start/stop set up for customers

dry contact connection.

• Pentra PLC outputs control IDEC's RV1H pilot relays

rated to 6 amps.

• The RV1H relays are plugin and 100% field replaceable.

• Pentra PLC/HMI have been load stress tested to an ambient

temperature range of -10F to 120F.

• HMI provides onboard help with troubleshooting tips. Using

QR codes (shown) on screen, users can access detailed

troubleshooting tips and video's via Legacy's dedicated web server.

• Pentra PLC/HMI have been load stress tested to an ambient

temperature range of -10F to 120F.

• HMI provides onboard help with troubleshooting tips. Using

QR codes (shown) on screen, users can access detailed

troubleshooting tips and video's via Legacy's dedicated web server.

Important Note:

Other chiller manufacturers use board-mounted

relays... when they go bad, the entire circuit board must

be replaced resulting in longer chiller downtime.

Legacy Chillers use "Plugin" Control Relays for quick easy replacement with much less downtime and cost!

relays... when they go bad, the entire circuit board must

be replaced resulting in longer chiller downtime.

Legacy Chillers use "Plugin" Control Relays for quick easy replacement with much less downtime and cost!

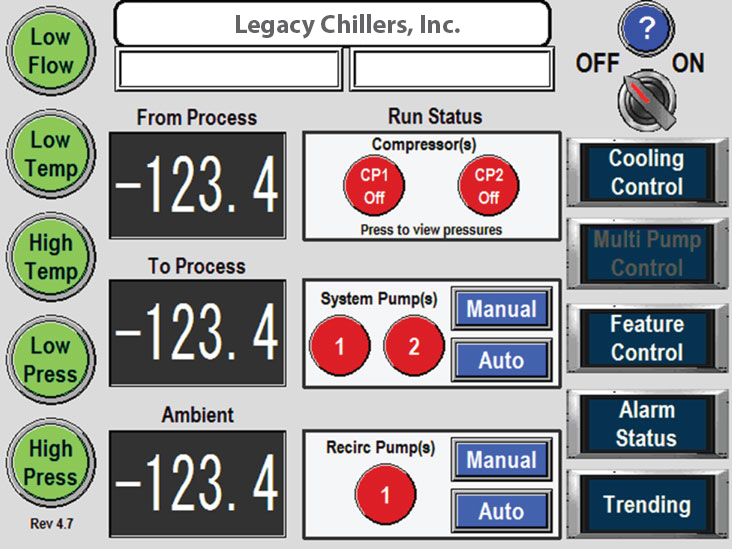

The Legacy Touch-Screen User Interface

with Pentra Microsmart,

Programmable Logic Controller (PLC).

Standard on ALL Models!

Legacy Chillers Touch-Screen User Interface Examples

Available Options...

VPN Secure Remote Connectivity

Virtual Private Networking (VPN) is used to connect a process chillers remotely over a secure network connection.

A VPN can be use to remotely connect a chiller via an Intranet or Internet connection. VPN typically does not require a firewall configuration.

A VPN can be use to remotely connect a chiller via an Intranet or Internet connection. VPN typically does not require a firewall configuration.

- Wired or wireless versions

- Ewon comes with NO monthly

licence fees

licence fees

Ethernet

Connectivity

• Industrial grade umanaged

network switching

network switching

• Connection Allows

Interface with:

- Ensures maximum economy

and low running cost

and low running cost

• Standard interface with

Legacy software - this option

can be added at anytime with

hardware install.

BACnet Gateway and Router

The Babel Buster BB@ is a BACnet gateway and router. It may be used as either or both, in various ways for different applications In its simplest form as a router, it will route MS/TP network to a single BACnet IP network. It may be use as a router to interconnect multiple BACnet MS/TP via IP networks. It may even be used to traverse NAT routers on a WAN connection to connect distant buildings via Internet.

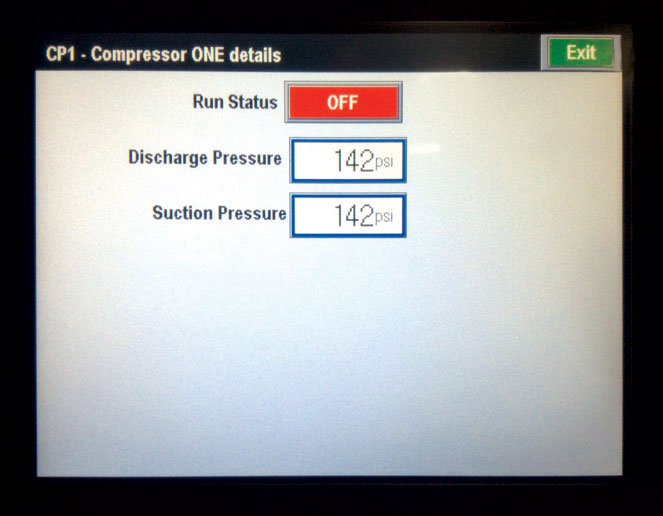

Compressor Operation Status

and Pressures

and Pressures

Chiller Main Operation Screen

Chiller Alarm Status

Screen 1

Screen 1

Remote Idec Touchscreen

Control Panel

Control Panel

Have Complete Control of your Legacy Chiller from Anywhere in Your Facility.

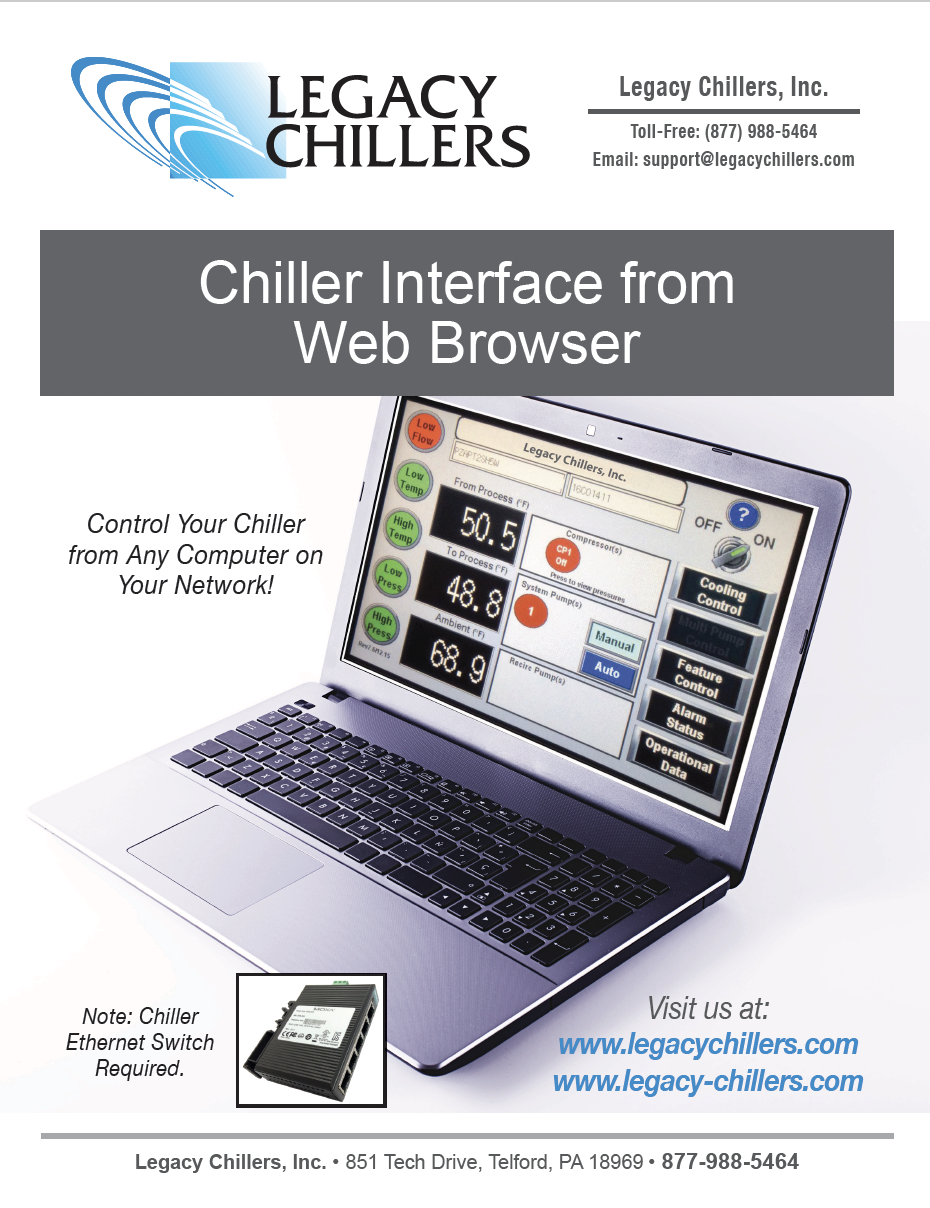

Control Your Legacy Chiller from Any Computer on Your Network.