Air-Cooled Fluid Process Chillers by far are the most common applications for process duty service. These chillers remove heat from

your process and reject that heat to the outdoor air. Air-cooled process chillers tend to be easier and less expensive to service, cost less

than water-cooled process chillers and offer a wide variety of options (such as economizers), providing excellent design flexibility.

your process and reject that heat to the outdoor air. Air-cooled process chillers tend to be easier and less expensive to service, cost less

than water-cooled process chillers and offer a wide variety of options (such as economizers), providing excellent design flexibility.

Air-cooled chillers can be configured as Packaged Chiller Systems or Split-Systems (Outdoor Condenser, Indoor Chiller).

Standard Features:

• ETL listed

• Remote Condenser Coil

• Microprocessor controller with touchscreen HMI

• STAINLESS STEEL, brazed plate evaporator

with 1/2 inch insulation and secured in a

steel bracket [1]

• Scroll compressor with crankcase heater

• Suction accumulator [1]

• Water flow switch

• Hot gas by-pass capacity control [1]

• 24V control transformer

• Direct drive condenser fan motor

• Rust resistant, high CFM, aluminum condenser fan blade

• Condenser(s): copper tube/aluminum fin

• Compressor motor contactor

• Condenser motor and control circuit fusing

• Painted, galvanized sheet metal cabinet

• 1/2 inch insulation on all water and refrigerant lines

• Liquid line drier, sightglass, solenoid, TEV

• Complete refrigerant charge from factory 407C standard [1]

• ETL listed

• Remote Condenser Coil

• Microprocessor controller with touchscreen HMI

• STAINLESS STEEL, brazed plate evaporator

with 1/2 inch insulation and secured in a

steel bracket [1]

• Scroll compressor with crankcase heater

• Suction accumulator [1]

• Water flow switch

• Hot gas by-pass capacity control [1]

• 24V control transformer

• Direct drive condenser fan motor

• Rust resistant, high CFM, aluminum condenser fan blade

• Condenser(s): copper tube/aluminum fin

• Compressor motor contactor

• Condenser motor and control circuit fusing

• Painted, galvanized sheet metal cabinet

• 1/2 inch insulation on all water and refrigerant lines

• Liquid line drier, sightglass, solenoid, TEV

• Complete refrigerant charge from factory 407C standard [1]

• Extended warranty: See your quote or latest IOM booket

revision

[1] denotes optional items on most competing brands.

revision

[1] denotes optional items on most competing brands.

Available Options:

• 4 year extended compressor warranty

• Casters (factory mounted)

• 115 volt (rain tight) service outlet

• Fused disconnect

• Non-fused disconnect

• Phase monitor

• Compressor fusing

• Fan cycle control

• Flooded condenser with receiver/head pressure control (-20 °F)

• Heated, flooded condenser with receiver/head pressure control (-20 °F)

• Factory installed evaporator heat tape freeze protection

thermostatically controlled

• Water pressure gauge set

• Fused, STAINLESS STEEL system process pump

• Pump suction isolation valve

• Dual system pump with HMI programable changeover

• Low flow by-pass valve system pump required

• "Gold" finned condenser coil (coastal protection)

• "Copper" finned condenser coil (coastal protection)

• Heresite-coated condenser coil (coastal protection)

• Water flow meter

• Auto city water make up solenoid

• Storage tank sight glass (Tank models only)

• Tank low liquid level indicator (Tank models only)

• 4 year extended compressor warranty

• Casters (factory mounted)

• 115 volt (rain tight) service outlet

• Fused disconnect

• Non-fused disconnect

• Phase monitor

• Compressor fusing

• Fan cycle control

• Flooded condenser with receiver/head pressure control (-20 °F)

• Heated, flooded condenser with receiver/head pressure control (-20 °F)

• Factory installed evaporator heat tape freeze protection

thermostatically controlled

• Water pressure gauge set

• Fused, STAINLESS STEEL system process pump

• Pump suction isolation valve

• Dual system pump with HMI programable changeover

• Low flow by-pass valve system pump required

• "Gold" finned condenser coil (coastal protection)

• "Copper" finned condenser coil (coastal protection)

• Heresite-coated condenser coil (coastal protection)

• Water flow meter

• Auto city water make up solenoid

• Storage tank sight glass (Tank models only)

• Tank low liquid level indicator (Tank models only)

AIR-COOLED

SCROLL PROCESS CHILLERS

For More Information... Call Us Toll-Free at: 877-988-5464.

Click on a Chiller Model Below to Download a Spec Sheet

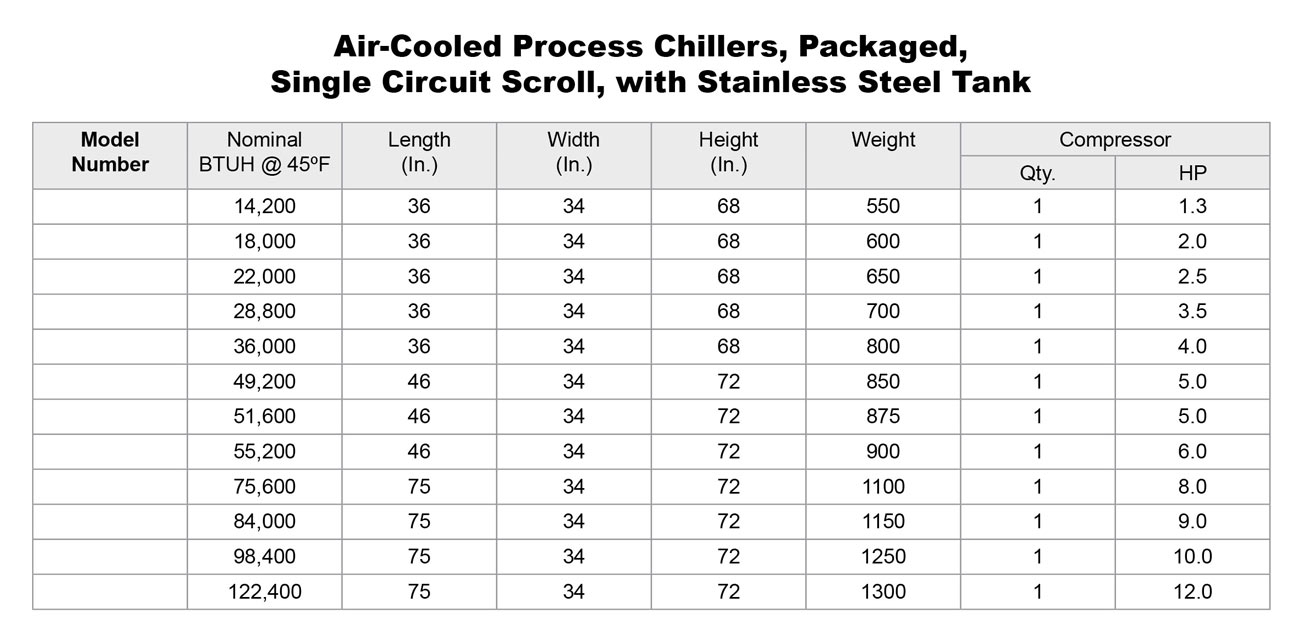

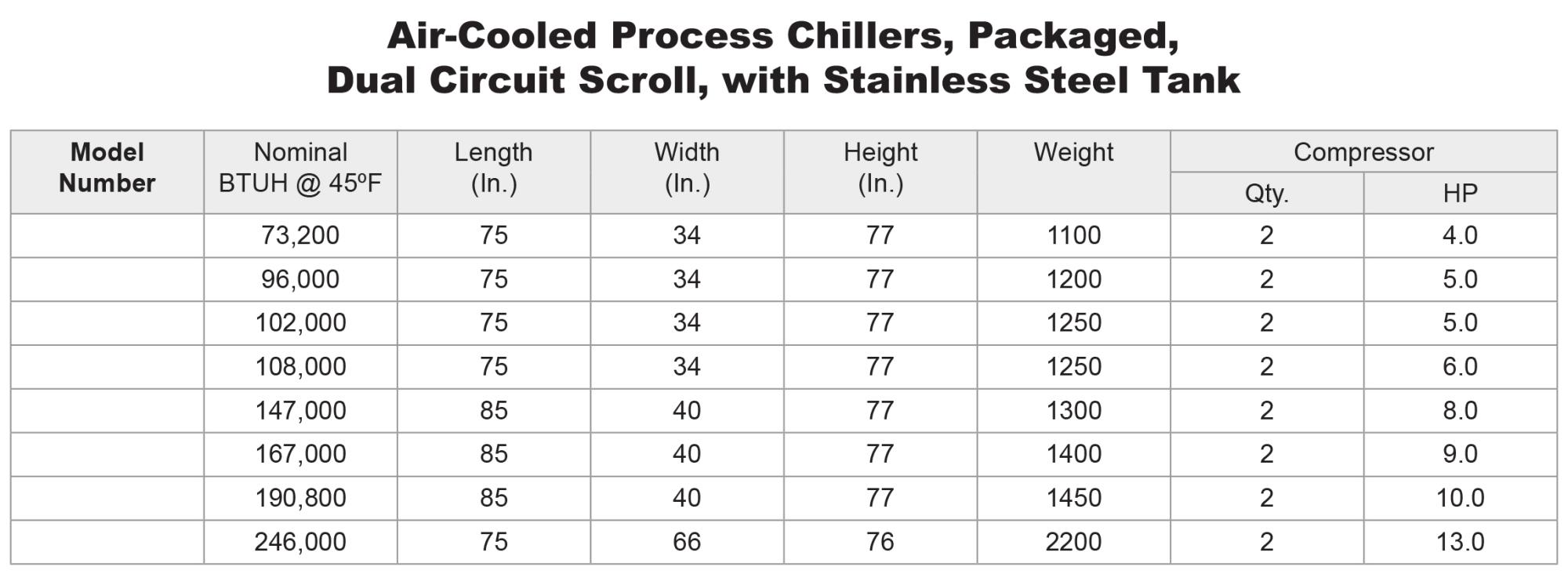

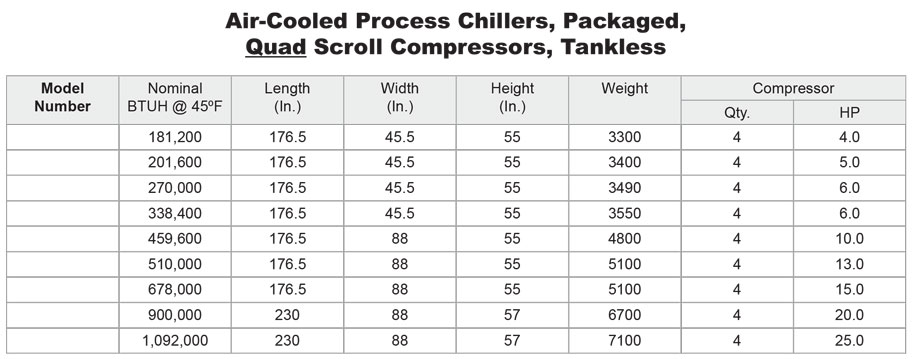

Note: Air-Cooled Process Chiller Capacities based on

ARI Standard 45ºF LWT and 95ºF AMB.

ARI Standard 45ºF LWT and 95ºF AMB.

PZAT4S - shown with

optional Coil Louvers

and Disconnect

optional Coil Louvers

and Disconnect